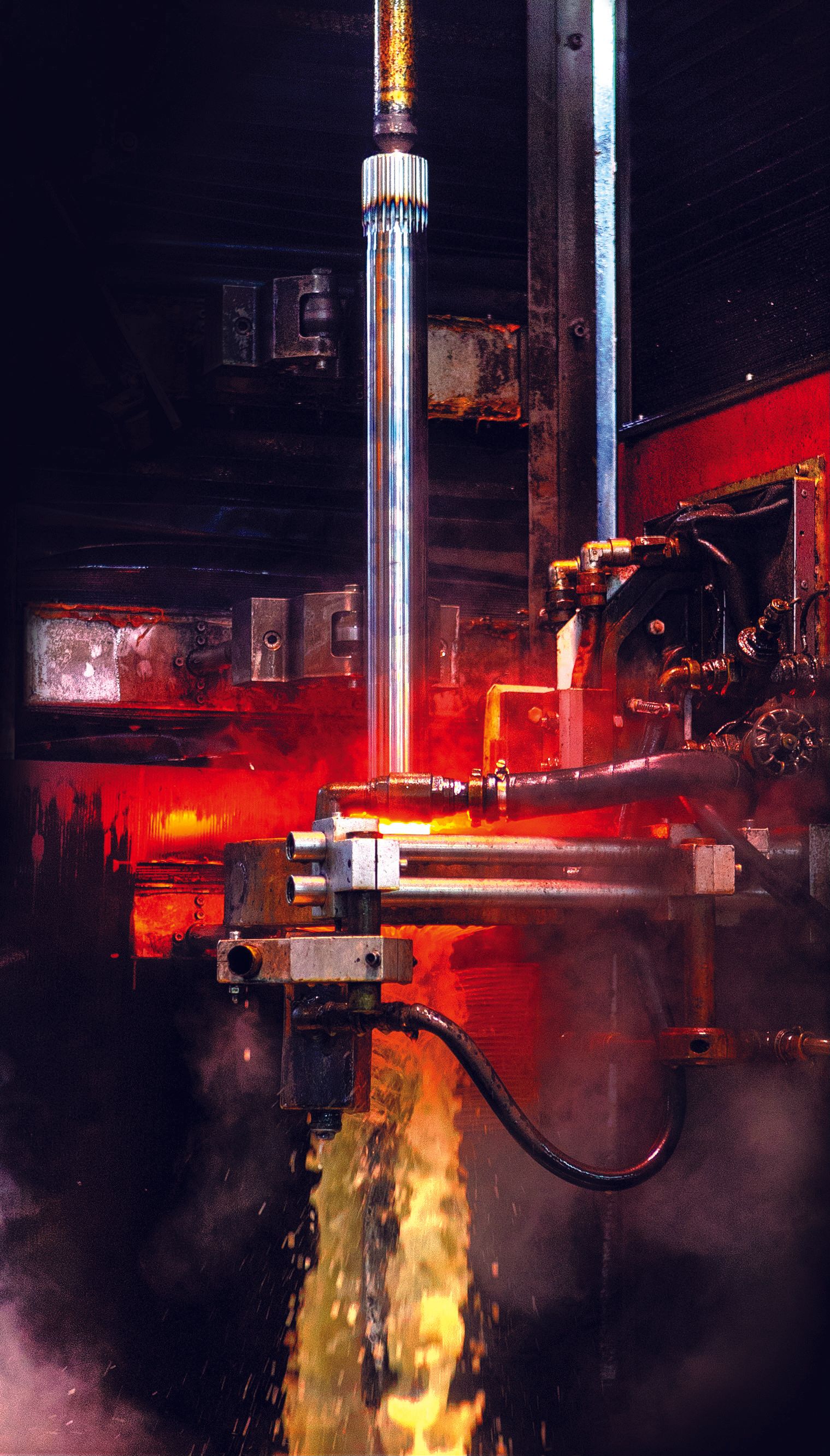

Productive Process

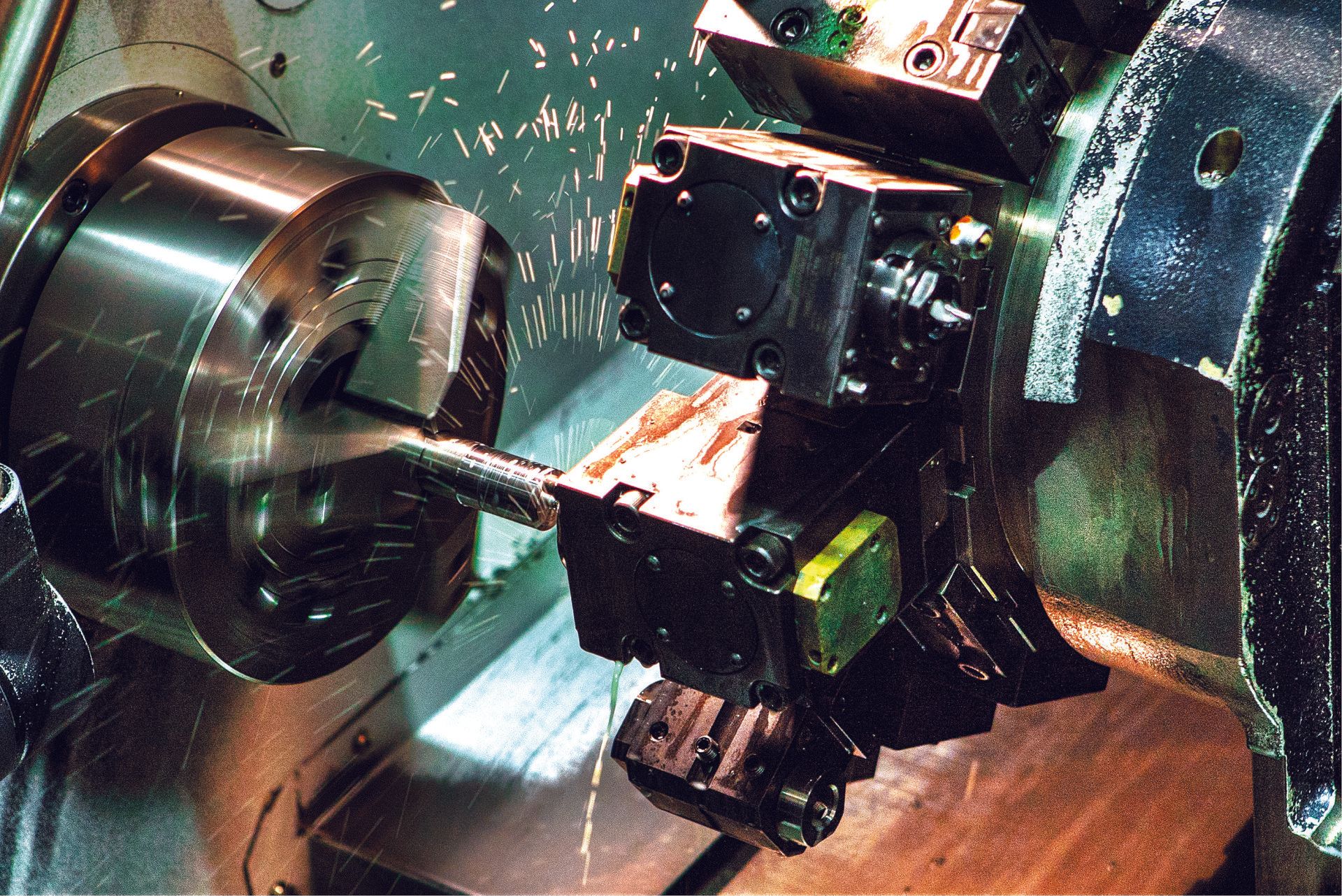

The finished product is the result of a series of work steps performed by specialized personnel with machines of the latest generation for

facing -> turning -> milling -> drilling -> grinding -> toothing -> broaching -> induction hardening

The manufacturing system necessary to model the elements in the removal slivers technique uses the most advanced technology available and guarantees the base for the construction of the "mechanical processing" and ensures precision in the assembly process.

Trenton stands out for its efficiency and innovation in its production processes. Here’s an overview of the key aspects of the company's production processes:

1. Research and Development

- Continuous Innovation: Trenton constantly invests in research and development to improve its products and processes. This includes analyzing market needs and collaborating with industry experts.

- Prototyping: Before mass production, prototypes are created to test new ideas and ensure they meet quality and performance standards.

2. Production

- Advanced Technology: The company uses state-of-the-art machinery and modern production technologies to ensure precision and efficiency. Automated processes help reduce production times and improve product quality.

- Quality Control: Every stage of production undergoes rigorous quality checks. Tests and inspections are conducted to ensure that each component meets company standards and customer specifications.

3. Supply Chain Management

- Selected Suppliers: Trenton collaborates with trusted suppliers to ensure high-quality materials. Careful supply chain management is essential to maintaining high standards at every stage of the production process.

- Efficient Logistics: The company adopts logistical strategies to optimize distribution and reduce delivery times, ensuring that products are available when and where they are needed.

4. Sustainability

- Sustainable Practices: Trenton is committed to sustainable production practices, aiming to reduce its environmental impact. This includes optimizing processes to minimize waste and using recyclable materials.

5. After-Sales Support

- Continuous Support: After the sale, Trenton offers technical support and consulting to ensure that customers optimize the use of the products. This customer-oriented approach contributes to loyalty and satisfaction.